An electric boosting system in the equalising section is a simple and effective method of improving thermal homogeneity, especially for NNPB, TG and QG.

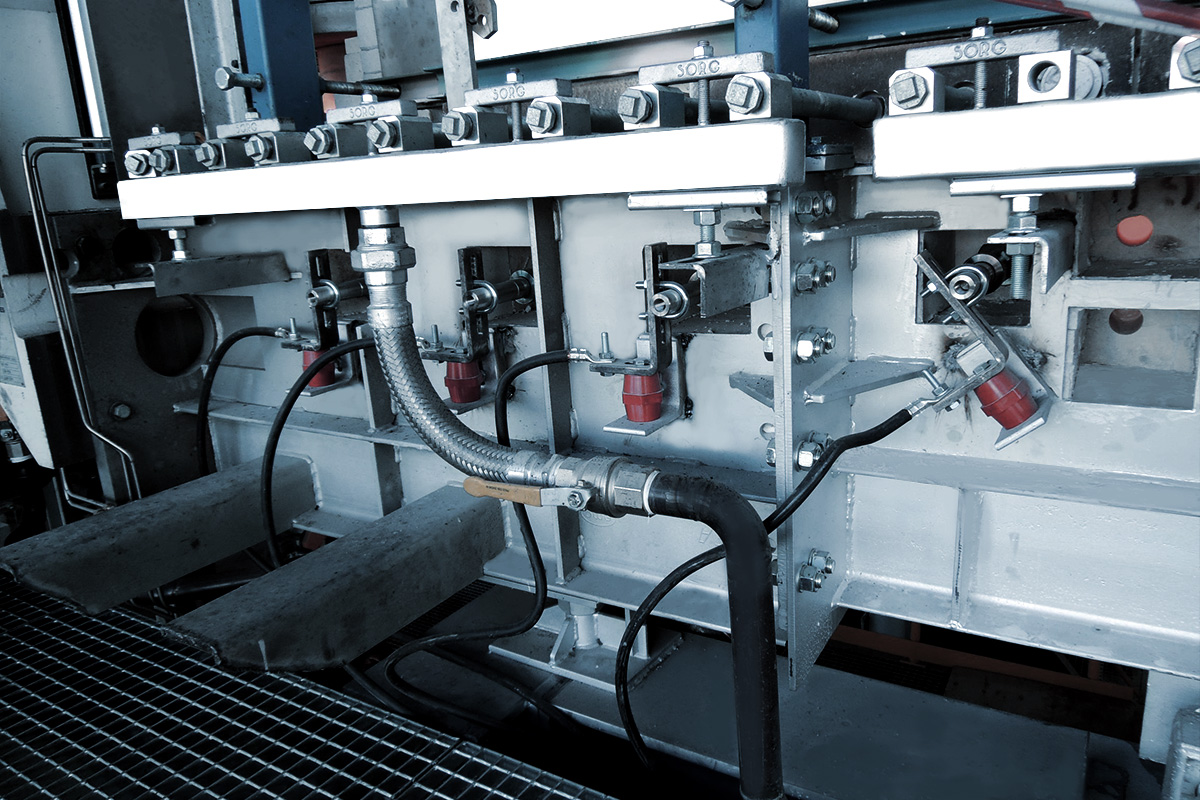

The electrodes are specially designed for use in forehearths and consist of a molybdenum inner part attached to a high-temperature steel connector. They are installed horizontally through the channel sidewalls, are naturally air-cooled and do not normally require additional cooling.

The electrical equipment comprises several single-phase, double-wound transformers, each with a thyristor unit to give stepless control of the applied power.

All electrical equipment is installed in totally enclosed sheet steel cabinets, built and tested to current European harmonised EN standards. The heating circuit can be arranged to heat either the glass at the channel side or the bottom glass.

ADVANTAGES

- Direct influence on the glass at the channel sides and/or bottom – areas that are usually difficult to influence

- Rapid reaction to adjustments makes it easy for operating personnel to optimise performance

- Very low power requirement (usually less than 10 kW)

- Can be installed on working forehearths with minimum disturbance

CHARACTERISTICS

All systems feature two special safety functions:

1. A unique firing pattern that results in a very low carry-over voltage into the bowl.

2. A safety earthing function ensures there is absolutely no voltage to earth in the bowl when work is being carried out.

The electrodes are often installed during a cold repair of the forehearth, but they can also be added to an existing line during operation.