A collective

RESPONSIBILITY

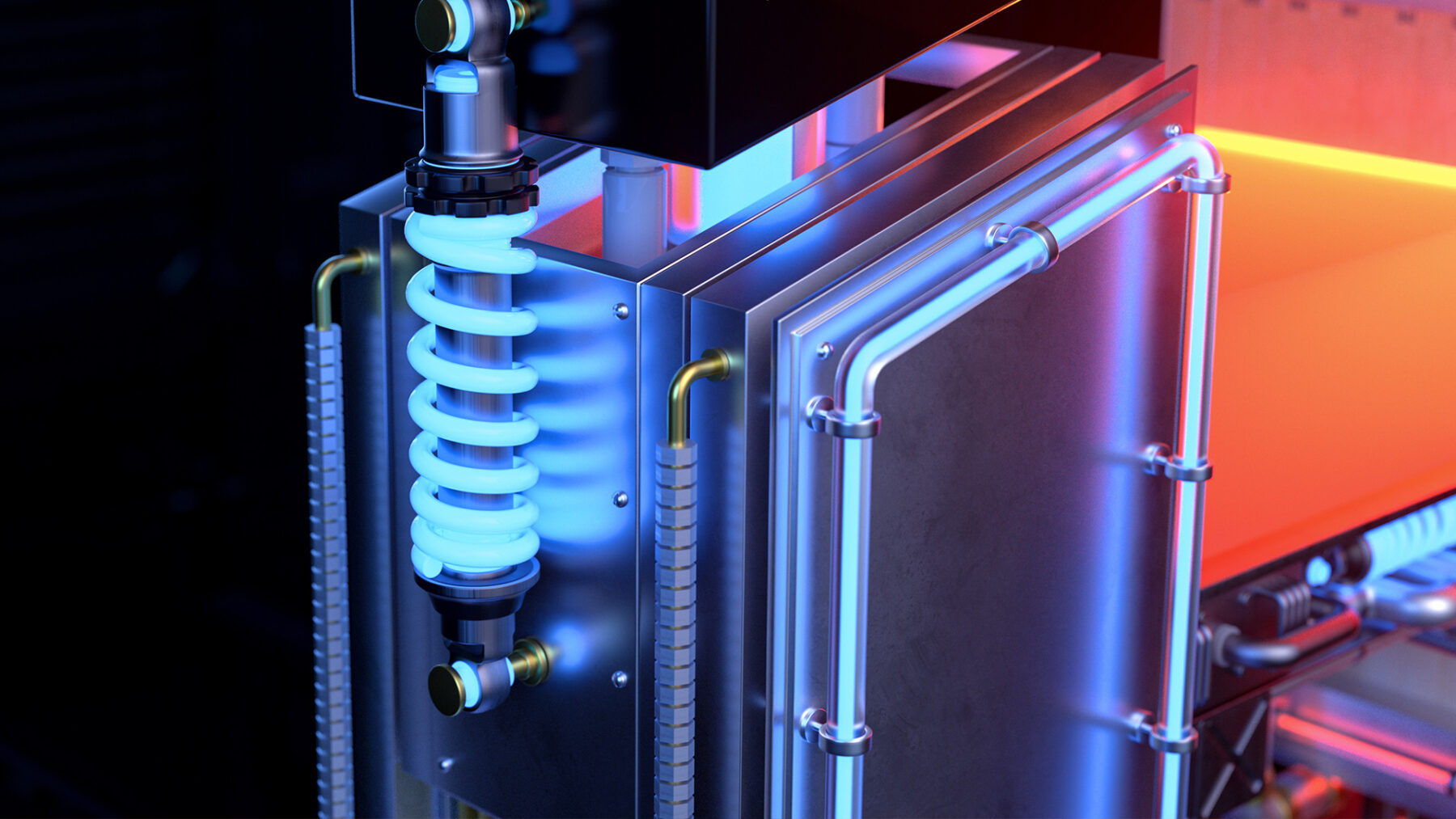

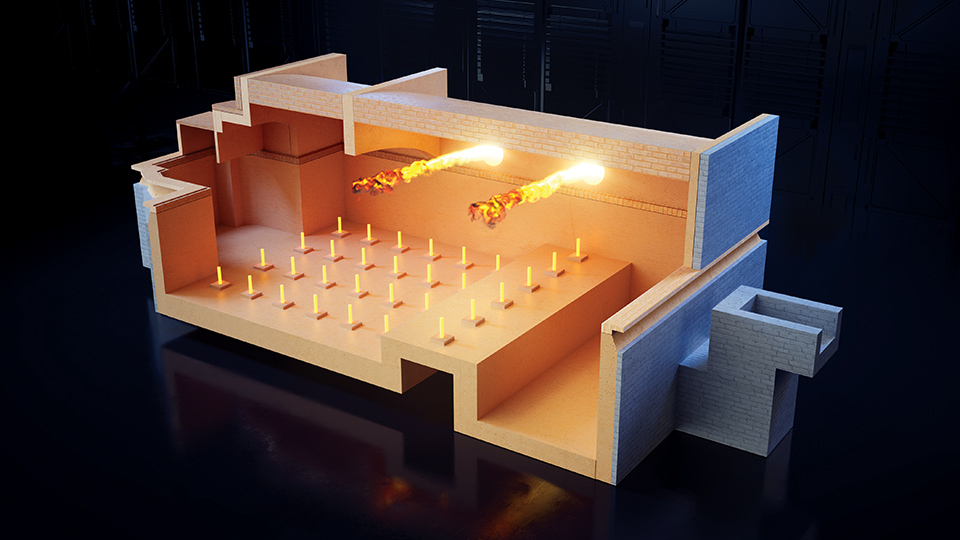

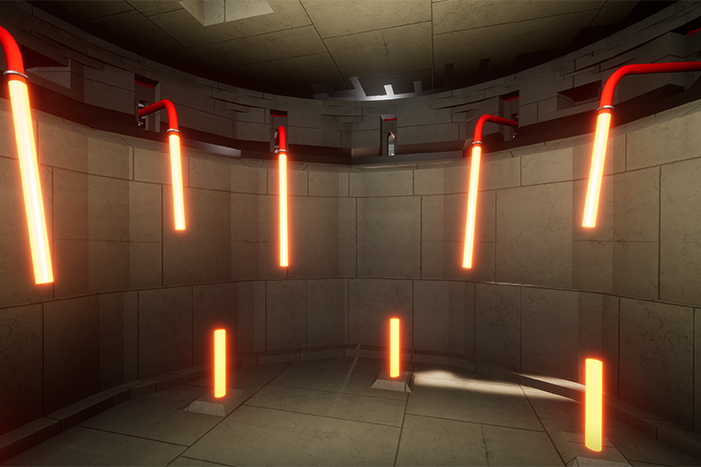

The decarbonisation movement has spread from policy-setting bodies to businesses and it’s now clear we all have a role in preventing extreme climate change. As a company with extensive technical expertise in sustainable glassmaking technology, we work with our customers as well as recognised industry bodies to develop and implement sustainable melting and conditioning technologies worldwide.