VSM® furnaces use the cold-top melting process. The patented SORG® rotating crown batch charging system is used to charge batch across the whole melting surface. This type of system requires no moving parts within the furnace superstructure. The rotating crown batch charger and the enclosed superstructure ensure a simple dust retention and almost no in‐factory dusting.

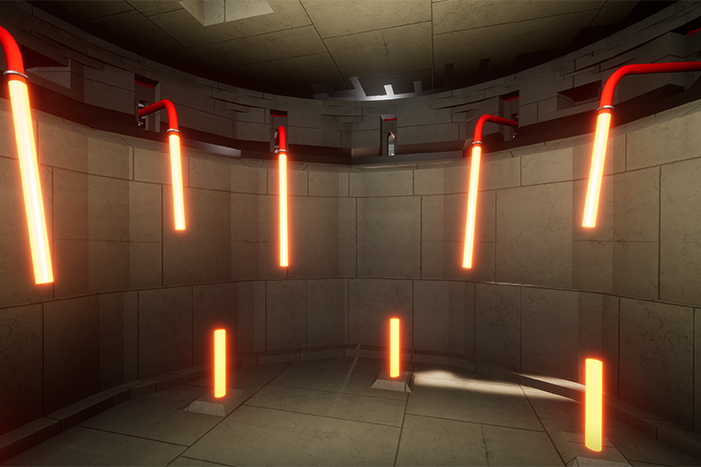

Specially developed SORG® Top Electrodes are installed in all VSM® furnaces. They are inserted through the furnace superstructure and enter the glass bath through the surface. They can be swung out of the furnace for inspection and exchange. Using these electrodes, the refractory material is subject to much less wear and damage.

ADVANTAGES

- No in-factory dusting

- No CO2 and NOx emissions from combustion

- Top electrodes ensure longer campaign and easy maintenance

- Very low waste gas volume (only batch gases)

- Low energy consumption

CHARACTERISTICS

- Typical glass types: soda-lime glass, C-glass, borosilicate glass, fluoride opal glass

- Typical products: containers (bottles, jars, flacons), lighting ware, tableware, fibres, stemware, high-quality flacons, tubing

- Performance: 3 – 200 t/24h

- NOx emissions from combustion: zero (dry, 8% O2)