SORG Group has successfully completed the reconstruction of the AV3 furnace in Llodio, Spain, for glass packaging designer and manufacturer Vidrala.

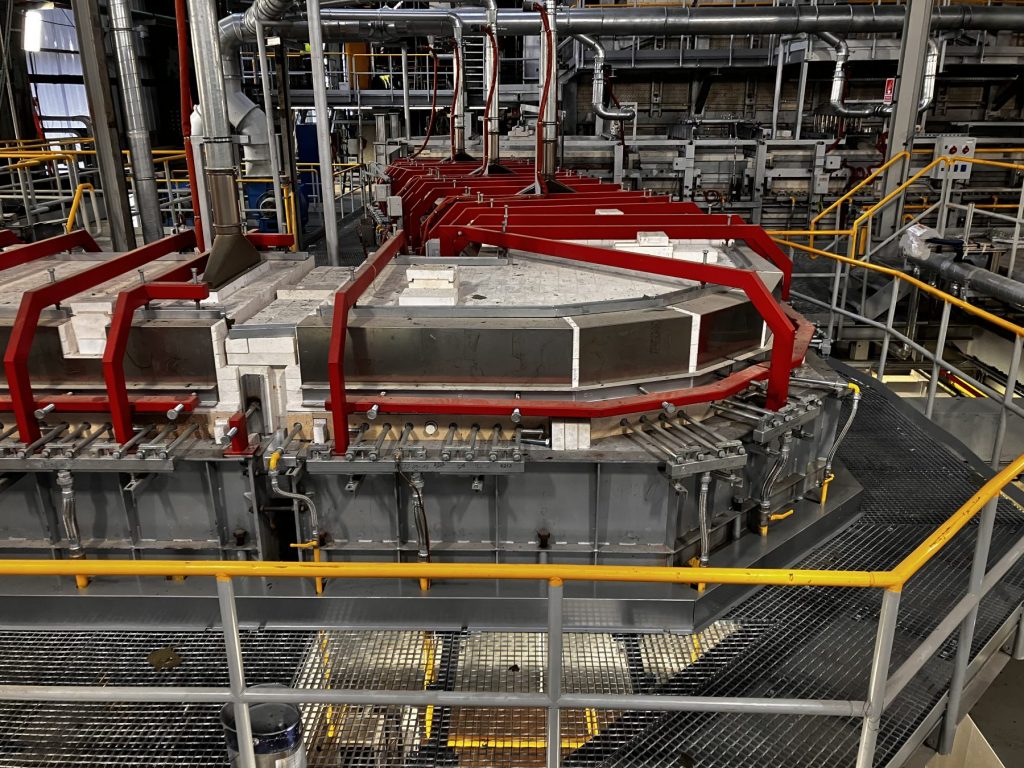

Following a successful campaign, the AV3 furnace, originally constructed by SORG, required a comprehensive rebuild. The regenerative endport furnace, which produces containers in a variety of glass colours, has now been upgraded to the latest technical standards, aligning with Vidrala’s strategy to provide exemplary service to its customers.

In addition to the technical enhancements of the furnace design, which now incorporates a greater proportion of electric energy than before, SORG supplied several key systems. These included the combustion air and waste gas system, the gas heating system, the electrical heating system, the measurement and control system and a redundant SCADA software control system. The batch feeding of the melting tank is managed via EME-NEND® batch chargers. For glass conditioning, SORG provided an STW working end and 340S+® forehearths, along with the necessary planning and equipment. The installation of the equipment and the commissioning of the furnace were overseen by Nikolaus Sorg.

The steel and refractory services were executed by SKS. This work included draining and demolishing the furnace, supplying and erecting the furnace steel, and completing the refractory construction of the furnace and glass conditioning system. SKS also handled the heating up and charging of the furnace, the hot insulation and the ceramic welding to seal the joints. The disposal of all refractory materials concluded the SKS service package.

The successful reconstruction of the AV3 furnace is a testament to the strong collaboration between Vidrala and SORG Group, showcasing their combined technical expertise and dedication to strengthening the glass manufacturing industry.